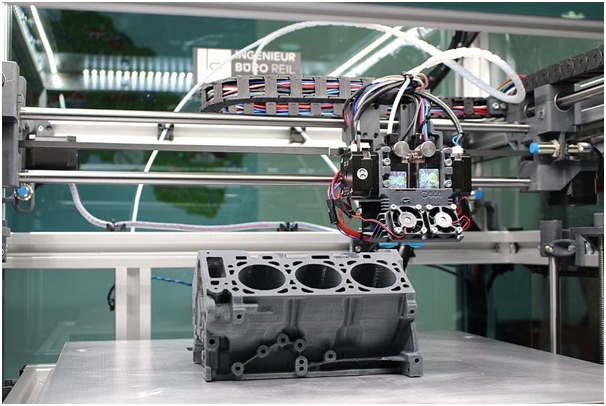

3D printing technology has come a long way over the past few decades. These days, you can purchase an entry level 3D printer for just a few hundred dollars. This price tag can get you started on the hobby at home. However, if you plan to use your printer for professional purposes expect to pay $4,000 or more. 3D printing works by overlapping thin layers of a substance, usually plastic, silicone or carbon fiber, into a particular shape.

This technology has been around for decades, but it’s only now gaining mainstream popularity. 3D printing is now being used by industry leaders in healthcare, aerospace and auto manufacturing. The process is faster and less expensive than machining, making it perfect for those smaller quantity items or for creating inexpensive prototypes of parts for testing.

As 3D printing grows in popularity amongst major industries, consumer demand has grown as well. Many public libraries are making 3D printers available for use to the public. Stores such as Staples and UPS are offering 3D printing services to their customers, both in-store and online. The printers are getting faster and less expensive to run, which will only make the technology more popular as time goes on.

Back in the 1980s this technology was still in its infancy. Most people believed 3D printing was only useful for rendering aesthetic prototypes of models and parts. Thirty years later, the process has advanced to the point that some 3D printed parts are considered viable for industrial strength production. 3D parts have become so high quality, and the technology has become so easily accessible, that many hobbyists are creating their own auto parts to restore their collectable car.

3D Printing Classic Car Parts

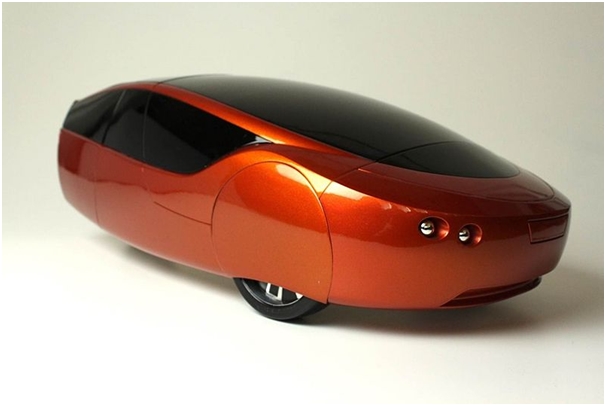

In 2014, the Swedish automaker Koenigsegg built the Urbee, a supercar with the bodywork and windows created by a 3D printer. Later that year, Local Motors debuted the Strati, a functioning vehicle that was entirely built out of 3D printed plastic and carbon fiber parts for everything except the powertrain.

Vintage car restoration has its own set of challenges. One of which is locating rare or obsolete parts. You may have classic car insurance, but that won't help you locate a discontinued OEM replacement part. 3D printing is now providing auto collectors a way to create their own parts for their modified car. Even with the advent of internet marketplaces, some classic car parts can be incredibly difficult to track down. Even if you do succeed in finding the part, often it will be extremely old or used. 3D printing allows you to custom make a brand new part to your exact specifications.

Of course, certain auto parts like engine blocks or wheel bearings cannot be 3D printed at home. These parts are subjected to significant heat and weight, therefore they must be manufactured using industrial machining processes. However, 3D printing is ideal for recreating those smaller plastic accessories such as door handles, knobs, dash pieces and cup holders. These are often the parts that break easiest and are hardest to find.

3D Printed Antique Car Parts

The process of 3D printing starts by scanning the entire body of the entire antique car. This detailed scan creates records of every curve and line of the vehicle. This scan is then fed into a computer and turned into a series of CAD drawings. A 3D printer can use these drawings to create the modified car part. The laser inside the printer then fuses together multiple layers of plastic, metal or carbon fiber to create an identical copy of the antique car part, accurate to the exact specification.

In a recent project, Artec 3D was able to scan a 1937 Ford Eifel inside and out to create a CAD duplicate model. This was later used to create replacement parts without even referring to the manufacturer's specs. That is how accurate 3D printing has become. Artec was able to create a new convertible top for this rare and valuable classic car. Artec 3D is now working to scan more vintage cars. Their goal is to build an archive of data so rare collectible car parts can easily be 3D printed based on their specifications. It’s smart to have modified vintage car insurance, but it’s also great to have access to 3D printing technology to create those hard to find parts.

Porsche is one automaker that has embraced the idea of 3D printing. Porsche has a cult following of enthusiasts who like to build and restore some of their classic models. Porsche still carries spare parts for their vintage cars, but their stockpile is steadily dwindling. Certain components have become extinct over the years and now Porsche has turned to 3D printing to manufacture nine of their previously discontinued parts for certain limited production models. These models include the Porsche 959, 964 and the 911 Speedster. Porsche is still stringent with their quality control and all the parts are tested to make sure they meet OEM standards. Porsche has been happy with the results thus far and they’re already planning to expand their 3D parts printing operation.

Where To Buy 3D Printed Modified Car Parts

Whether you want to print your own car parts or purchase those rare parts from another printer, there are several reputable online marketplaces for you to explore. Here’s a list of the top three options right now.

Shapeways

Shapeways offers a 3D printing service for almost any part you could want. They also have a marketplace with thousands of classic car parts. Their goal is to become the one-stop-shop for all your 3D printed needs. If you don’t want to experiment with printing your own parts, Shapeways is a great option. Ttheir service will cost more than doing it yourself, but you can be confident that you’re getting the highest quality available in a 3D printed part.

MyMiniFactory

MyMiniFactory has a database of collectible car models ready for 3D printing. Here you’ll be able to download their models and use them to create parts for your own projects. It’s important to note that physical parts are not available for sale on the site. They only offer models so you can print your own.

If you have access to a FDM 3D printer, you will be able to manufacture any of these parts from the comfort of your own home. The best part of MyMiniFactory is the price. It’s completely free to download, use and distribute their 3D models. However, they do give you the option to donate a few bucks for their service, which is always a nice gesture. The site has a lot more than just car parts. It’s a great free resource for 3D printing hobbyists.

Thingiverse

Thingiverse is an extremely popular website in the 3D printing community. The site features a huge selection of 3D printed modified car parts and other car related accessories. The site has virtually every kind of “thing” you can imagine and it’s a must visit if you own a 3D printer.

The Future of 3D Printing

One thing is for certain, 3D printing is here to stay. We’re only seeing the beginning of this technology and we will continue to see rapid advancements in the coming years. 3D printed parts will become cheaper and higher quality, giving antique car owners access to all the hard to find parts.

Featured Image Credit: pxfuel

In Post Image Credit: Kholoudabdolqader / Wikimedia Commons